Sus304 Heat Exchangers Large Ultrasonic Cleaning Tank For Industrial Cleaning Equipment Divided Tank

Introduction

Ultrasonic cleaning is a technology that uses high frequency sound waves (ultrasonic: above the range of human hearing) to agitate an aqueous or organic medium (cleaning chemistry) that in turn acts on contaminations adhering to substrates like metals, plastics, glass, rubber and ceramics. Contaminants can be dust, dirty, oil, pigments, grease, polishing compounds, flux agents, fingerprints, soot wax and mold release agents, biological soil like blood, and so on

Ultrasonic technology is powerful because:

1.Sound waves created by transducers are passed through the water creating vibrations that shake organic material loose from instru�ments

2.Microscopic bubbles succumb to pressure and implode, creating a stream of water, which when next to the surface of an instrument will push gross soils off

3.. Hidden bioburden is removed from microscopic bubbles, created by the vibrations that when they encounter debris bump it free from the instrument

Ultrasonics efficiently removes:

carbons

varnishes and paints

petrochemicals

oil and grease

metal shavings

lubricants

rusts

carcinogens

polymers

Ultrasonics can clean a wide range of filters including:

extruders and pumps

filter elements

filter vessel assemblies

polymer pumps

spin and screen packs

valves

spinnerets

die plates

porous metal

pleated metal

woven screens

fiber metal felt

slotted wire

filters with alloys

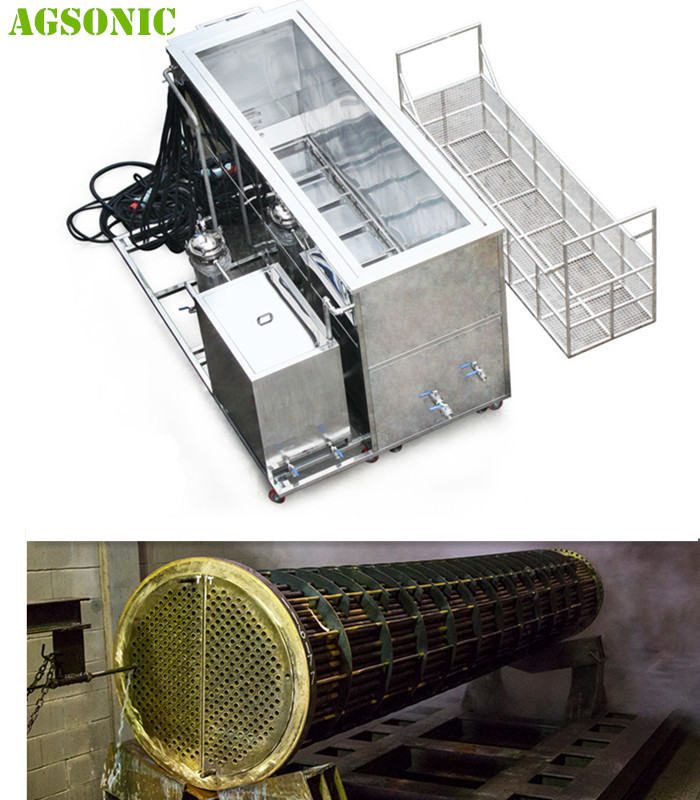

200cm X 150cm X 60cm Sonic Wave Ultrasonic Wave Radiator Cleanning Heat Exangers Ultrasonic Cleaning Tank

The cleaning of heat exchangers is a labour intensive and costly business. In most cases high pressure cleaning will do the job using many litres of (hot) water and creating a substantial waste stream what should processed. Next to this the factor time is also an important issue.

The use of ultrasonic energy offers an alternative en a much more efficient way to clean heat exchangers. The generated cavitation separates the contamination without damaging the object.

Routine cleaning

Cleaning the ultrasonic cleaner and replacement of the cleaning solution is necessary at least daily or more frequently if solution soiled.

Performance testing

The efficacy of the ultrasonic cleaner should be tested at least weekly. The results of the testing shall be documented as part of the proof of process. Sonic cleaners fail for many reasons. Tests should provide a means of monitoring the variables that influence the effectiveness of the ultrasonic cleaning process. Some of these variables are water, time, detergent, enzyme, temperature, high pH, agitation, speed, initial heat, drying, obstructions, and insufficient amount of chemicals and equipment faliure

important factors for a succesfull cleaning process:

· Construction of the cleaning bath

· Intensity and right positioning of the ultrasonic transducers

· Process & chemistry control

Knowledge and experience in the field of ultrasonic cleaning are indispensable.

The right combination and implementation of these factors makes it possible to remove effectively residues of hydro carbons and several other refinery side products from the heat exchanger and this in a shorter time than other conventional cleaning techniques.

Ultrasonic - Safe, environmental friendly and efficient cleaning

Ultrasonic Radiator Cleaning Sheridan & Buffalo,

Radiators are essential parts of every heating or cooling system whether they’re used in buildings or vehicles. Radiators facilitate the transfer of thermal energy from one medium to another, allowing the regulation of air temperature in a given space. Like any HVAC part, radiators tend to accumulate dust and dirt over time. When too much debris is present in the radiator, its performance is stunted and energy efficiency is negatively impacted.

Unlike most parts of an average heater or air conditioner, the radiator can be pretty sensitive to the force applied during cleaning. Too much force can damage it while too little can allow dirt to linger inside. To strike the perfect balance between effectiveness and safety, we recommend ultrasonic cleaning for your radiators.

Captain Clean utilizes ultrasonic cleaning technology for the total removal of all debris in your radiator. This method makes use of powerful sound waves blasted at high and low frequencies to agitate particles that cling tightly to your radiator’s body. When combined with gentle aqueous cleaning solutions, ultrasonic cleaning can flush out a few years’ worth of dirt from your radiator and help it perform like new.

Using aqueous (water based) detergents, ultrasonic equipment effectively removes oil, swarf and other contaminants from a wide range of components such as heat exchangers, lube oil filters, valves, radiators, coolers, turbine and drilling equipment used in the oil and gas industry. This maximises throughput and increasing productivity, making it one of the most effective and environmentally friendly ways for cleaning these parts and components.

We are also experienced in supplying ultrasonic cleaning systems for on-board processing, providing and adapting functions to suit your specific requirements.

Ultrasonic Cleaner Auto Industry

We are the manufacturers of custom built Ultrasonic Cleaning machines for degreasing and cleaning of auto parts for OEMs , work shops , job works and auto-restoration industry. We expertise in providing customized designed solution for auto parts cleaning.

Ultrasonic cleaning is a water based cleaning solution where ultrasonic transducers are used to provide cavitation agigation insude the tank which has waer and suitable chemical to clean oil,dirt,debree,grease and other contaminants from various types of auto components.

We expertise in all types of ancilary parts washing like brakepads, steering coloumns, crank shats, pistons, valves, gaskets, clutch pads, mirrors and many more.

Features of the machine:

•Low maintainence machine

•Heavy duty cleaning systems

•Chemical friendly- SS Rust proof body

•Industrial guage farication, build to last

•One year warrenty on any manufacturing defect

•Completely customized to suit the cleaning requirement

•Less human interfearance and less scope of error

•Accurate and uniform cleaning everytim

Powerful Industrial Ultrasonic Cleaner

The largest ultrasonic tanks can include tanks as big as 1,000 gallons or more. These units are meant for applications requiring lower frequencies (25-40 kHz), including larger or heavy duty equipment such as over-sized manufacturing parts, automotive and marine parts and large musical instruments. Units may have multiple built-in stages, including rinse and dry stations, and are sometimes automated

We all want to look our car shiny, and running smooth. And for this very reason timely servicing your car from inside out is one of the most important thing you should not avoid

Why Use Automotive Ultrasonic Cleaner?

There are so many uses for an ultrasonic cleaner in an auto shop. Ultrasonic car parts cleaning saves time by eliminating the need for manual scrubbing of auto parts covered with grease, oil, and other lubricants. Besides freeing up time, the hazardous chemicals can be replaced with biodegradable soaps. Specific examples of items that are commonly cleaned by a benchtop ultrasonic cleaner include filters, shock absorber parts, power steering parts, pistons, valves, fuel injectors, bearings – just to name a few. Larger industrial-sized units can be used for carburetor ultrasonic cleaning and ultrasonic exhaust manifold cleaning, where cleaning action is needed deep within the network of passages. This large capacity also allows for ultrasonic crankshaft cleaning and ultrasonic cylinder block cleaning as well the means to clean multiple parts at once.

Cylinder Heads And Engine Blocks Ultrasonic Cleaners

Automotive Ultrasonic Cleaners is primarily an aqueous tank systemthat uses ultrasonic energy to remove dirt, grease, oiland baked-on carbon from parts. Contaminants such aspaint, rust, glued-on gaskets, and heavy layers of bake don carbon can also be removed by ultrasonic cleaning but require more aggressive chemistries. Unlike someother cleaning processes, ultrasonic cleaning will notdamage intricate, lightweight, or easily damaged parts.

Our Ultrasonic cleaning process, can effectively clean the following components- Cylinder Heads And Engine Blocks And Aircraft Parts ,Aluminum castings, engine blocks, Carburetors, Cylinder Heads, Engines, Engine Components, Gear Boxes, Filters, Tubes and Valves.

AG Cylinder Heads And Engine Blocks ultrasonic cleaning machine are revolutionizing cleaning methods and processes on the Valve Plates , our Valve Plates And Aircraft Parts ultrasonic cleaning machine can clean all kinds of automotive, aircraft, and marine engine parts, ultrasonic technology for cleaning parts eliminates manual labor while providing you with superior cleaning action, most parts can be cleaned with environmentally friendly water-based solutions

Ultrasonic Cleaning Tank 200cm X 150cm X 60cm Sonic Wave

| Model |

T-180S (digital timer&heater, Power adjustable) |

| Capacity |

1800liter |

| Tank size |

200cm X 150cm X 60cm (LxWxH) |

| Ultrasonic power |

9KW adjustable |

| Heating power |

24KW |

| Timer |

1~99mins adjustable |

| Heater |

20~80C adjustable |

| Frequency |

40,000Hz |

| Power supply |

AC110~130V, AC 220~240V, 50/60 Hz |

| Tank material |

SUS304, 3mm thickness |

| Shell Material |

SUS304, 1mm thickness |

| Others |

With drainage, basket, lid |

| Warranty |

1 year& tech support for life |

Why Use Cylinder Head Engine Block Cleaning ?

Agsonics is renowned for their professional cleaning service to the motor industry.

How does ultrasonic cleaner technology clean?

Cavitation bubbles are vacuum cavities as tiny as red blood cells, or about 8 thousandths of a millimeter across. They are so small that it would take 1,250 of them lined up in a row to reach 1 cm long.

Under pressure of continuous vibration, these bubbles stretch and compress at a fast rate. Once they reach a certain size, as determined by the frequency and strength of the sound waves produced, the bubbles lose structural integrity and collapse violently. When these implosions happen near a surface, the bubbles emit high-powered streams of plasma that travel at more than 500 miles per hour and collide with, agitate and remove even very tiny particles and substances from that surface.

Suitable for all types of engine parts

AG engine block ultrasonic cleaning machine effectively and thoroughly clean all types of engine parts

01: Automotive: thoroughly removes carbon deposits, grease, and other types of dirty and contaminants from carburetor, exhaust manifolds, cylinder blocks, 2-stroke and 4 stroke motorcycle engines, snow machines, ATV cylinders and heads, and more.

02: Marine: Suitable for inboard and outboard motors, the cleaning chemistry is both thorough and gentle on the aluminum parts reducing the risk of future corrosion

03: Aircraft: The high performance demands of aircraft engines establish the need for an intensive cleaning process that will restore the engine part to near original condition, our engine block ultrasonic cleaning machine easily, thoroughly, and safely clean both large and small parts, turbine blades, fuel nozzles, generator components, brakes and other parts that require periodic cleaning are all effectively and thoroughly cleaned using the ultrasonic cleaning process

How the System Operates:

The system operates in the following manner:

- Parts are placed into the tank using the included stainless steel basket or other holding fixture.

- Once submerged, the START button is pressed, and the cover is closed. The ultrasonic system turns on, and the filter system turns off automatically. Parts are cleaned with the CROSSFIRE ultrasonic system at this time.

- The system will automatically turn off upon completion of the cycle.

- Operators can then return when the parts are clean.

The cover is opened and the batch of parts is placed onto the basket rest. Dripping liquids are directed back to the ultrasonic cleaning tank

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!